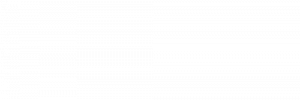

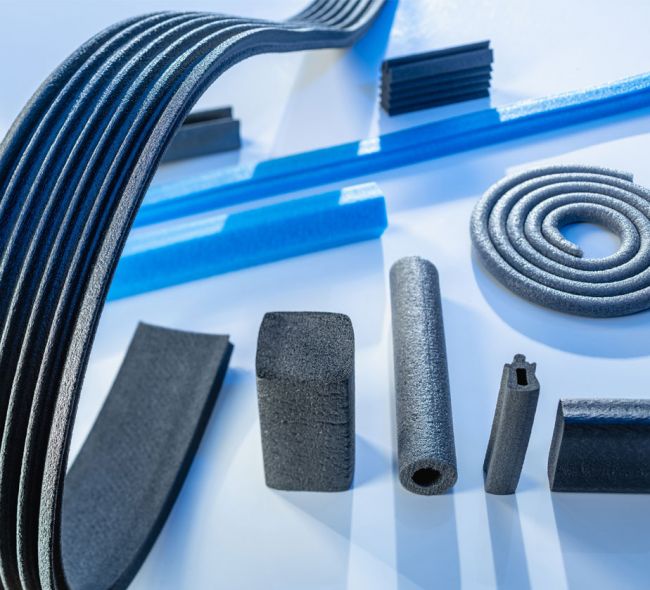

Extruded PE foam profiles

Polyethylene foam is a closed-cell material with excellent properties, e.g. low density, superior age and weather resistance, very good thermal and acoustic insulation rates as well as high resilience to acids, bases and other chemicals.

Properties

- closed cell structure

- excellent insulation properties (< 0,038 W/mK)

- low density

- excellent resistance against age & chemicals

- very low water absorption

- very low water vapor permeability

- environmentally neutral, no labelling obligation

Manufacturing

We manufacture your custom-made product according to your wishes and demands.

Production specials:

- additional fire protection

- lamination (self-adhesive tape & aluminium foil)

- laser imprint

- post processing & finishing

*When "extruded" the raw material is being moulded under pressure and endorsed with foaming agents into an extrusions die. After leaving the die the polyethylene foam expands into the desired shape.

Application areas

Cellular polyethylene is a highly versatile material suitable for a wide range of applications:

Thermal insulation: Profiles made of PE foam provide very low U-values (low heat conductivity in W/mK) and thus high thermal insulation rates. They are therefore of great import when it comes to energetically sustainable building.

Sealing: Thanks to their closed-cell structure and a smooth surface profiles made of extruded PE foam are water tight and especially suited for sealing tasks.

Packaging: Standard PE foam profiles, e.g. U- or L-shaped, are often used as edge protection in the glass, metal working or furniture industry.

Filling: Because of its low density and its mechanical properties PE foam is a very suitable filling material. In this area additional properties like its acoustic insulation rate are of particular interest too.

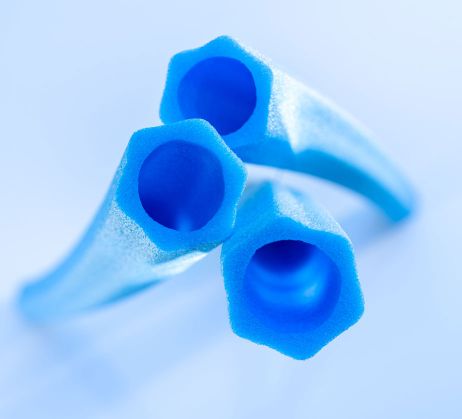

Energy efficient construction and reconstruction

with windowSafe® PE foam profiles

When it comes to the construction as well as the reconstruction of buildings saving energy has become a dominant topic over the last few years.

This is due to ecological as well as economical reasons and thus nearly all branches of the building sector are included in energy saving efforts.

Due to their excellent insulating properties polyethylene foam profiles have become more interesting in recent years. Today they are a vital part in of window and facade systems.

PE foam profiles are able to lower the thermal transmission coefficient of a window or a facade significantly.

Energy costs can be saved and pollutant emissions can be lowered.

Sustainability: PE foam & recycling

PE foam profiles are used for energy efficient building. But the sustainability issue does not end here.

As with other industrial products there is the matter of sustainable production and disposal.

Extruded PE foam profiles are mono-material products and can thus be recycled completely. Remains can be stripped of foreign materials such as adhesion tape or aluminium foil, shredded and again used for production.

In addition the polyethylene used for extrusion can be based on recycled or bio-based raw material.

You are interested in sustanainable PE foam profiles? Please contact us: info@windowsafe.de

|

Colours: |

grey, blue, white, anthracite |

|

Quality: |

FCKW- and HFCKW-free, 100% recyclable |

|

Density: |

25 to 35 kg/m³ |

|

Thermal conductibility: |

< 0,038 W/mK |

|

Water absorption: |

< 1% |

|

Compression set: |

< 30% |

|

Water resistance: |

excellent |

|

Temperature resistance: |

-40°C to +90°C |

|

Cell structure: |

regular and closed |

|

Further information: |

excellent insulation properties |

Your application needs different or additional technical properties (e.g. fire protection, a different color or density)? Please contact us for advice. Send request

Polyethylene - the material

Polyethylene, like polypropylene (PP) and ethylene vinyl acetate (EVA), belongs to the polyolefine group. Among all plastics they occupy a leading position worldwide in terms of production and use.

The history of polyethylene started in 1933 in the laboratories of the Imperial Chemical Industries (ICI) in Great Britain. There the first small amounts of a white powder were found in an autoclave. The material turned out to be polyethylene. However several years passed before the first plant begann production. Since the reaction to form polyethylene took place at very high pressures people at the time were talking about “high-pressure polyethylene".

This classification was later dropped and the internationally used designation based on density was adopted and standardized. The common name today is PE-LD (low-density). This became necessary because in 1953 chemists from the Max Planck Institute in Essen-Mühlheim and the US company Phillips Petroleum Comp. succeeded in polymerizing ethylene using certain catalysts even at low pressures. Since this “low-pressure polyethylene” had a higher density it was called PE-HD (high-density).

Today there are a number of processes for producing polyethylene with the types produced differing in their structure and properties. These include:

- PE-HD („high-density“)

… is produced at low pressures with certain catalysts and has a high density and higher crystallinity with low branching. PE-HD is particularly used in the packaging sector, e.g. for cleaning agent bottles. - PE-LD („low-density“)

… is produced at high pressures and temperatures, which creates highly branched polymer chains and low densities. PE-LD is primarily used for bags and films. - PE-LLD („linear-low-density“)

… linear very low density polyethylene whose polymer molecule has only short branches. PE-LLD is very resistant and flexible. For this reason and because of its relative transparency, it is primarily used for the production of cling film and bubble wrap. - PE-MD („medium-density“)

… medium density polyethylene is produced by mixing PE-HD and PE-LD or by copolymerization. (In the course of polymerization, two or more chemically different monomers are used instead of one monomer). - PE-X („crosslinked“)

… cross-linked medium to high density polyethylene, which has connections between the macromolecule chains. This improves both temperature and chemical resistance.

Polyethylene can be processed relatively easily. The most commonly used processes are: injection molding, extrusion and blow molding.

Polyethylene foam (PE foam) - the material

PE foam (also called cellular polyethylene) is a closed-cell material with very low density and very good mechanical properties that can be produced in different ways. A basic distinction is made between cross-linked and non cross-linked PE foam (PE-X and PE-E). In cross-linked materials the polymer chains are connected to each other thereby forming a three-dimensional network. With non cross-linked materials there is no connection between the chains.

- Cellular polyethylene, chemically cross-linked

Here the long hydrocarbon chains are connected to each other through a chemical reaction. Macromolecules are created. This effectively increases the thermal and mechanical stability of the foam. - Cellular polyethylene, physically cross-linked

Here the molecular networking takes place using a high-energy electron beam field. However this is only possible with thin foam (sheet goods). - Cellular polyethylene, non cross-linked

The molecular chains of the material are not connected to each other. For example, when extruding PE foam melted polyethylene is mixed with propellant gas (e.g. pentane or CO2) under high pressure and thereby foamed. The lack of networking results in a lower resilience to mechanical and thermal influences.