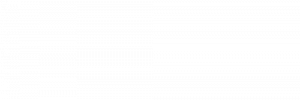

Extruded PE foam profiles

Polyethylene foam is a closed-cell material with excellent properties, e.g. low density, superior age and weather resistance, very good thermal and acoustic insulation rates as well as high resilience to acids, bases and other chemicals.

Properties

- closed cell structure

- excellent insulation properties (< 0,038 W/mK)

- low density

- excellent resistance against age & chemicals

- very low water absorption

- very low water vapor permeability

- environmentally neutral, no labelling obligation

|

Colours: |

grey, blue, white, anthracite |

|

Quality: |

FCKW- and HFCKW-free, 100% recyclable |

|

Density: |

25 to 35 kg/m³ |

|

Thermal conductibility: |

< 0,038 W/mK |

|

Water absorption: |

< 1% |

|

Compression set: |

< 30% |

|

Water resistance: |

excellent |

|

Temperature resistance: |

-40°C to +90°C |

|

Cell structure: |

regular and closed |

|

Further information: |

excellent insulation properties |

Manufacturing

We manufacture your custom-made product according to your wishes and demands.

Production specials:

- additional fire protection

- lamination (self-adhesive tape & aluminium foil)

- laser imprint

- post processing & finishing

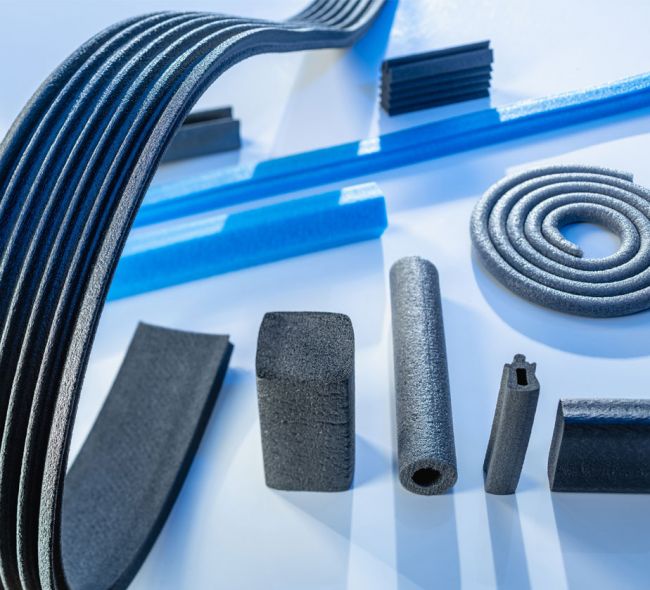

*When "extruded" the raw material is being moulded under pressure and endorsed with foaming agents into an extrusions die. After leaving the die the polyethylene foam expands into the desired shape.

Application areas

Cellular polyethylene is a highly versatile material suitable for a wide range of applications:

Thermal insulation: Profiles made of PE foam provide very low U-values (low heat conductivity in W/mK) and thus high thermal insulation rates. They are therefore of great import when it comes to energetically sustainable building.

Sealing: Thanks to their closed-cell structure and a smooth surface profiles made of extruded PE foam are water tight and especially suited for sealing tasks.

Packaging: Standard PE foam profiles, e.g. U- or L-shaped, are often used as edge protection in the glass, metal working or furniture industry.

Filling: Because of its low density and its mechanical properties PE foam is a very suitable filling material. In this area additional properties like its acoustic insulation rate are of particular interest too.

Energy efficient construction and reconstruction

with windowSafe® PE foam profiles

When it comes to the construction as well as the reconstruction of buildings saving energy has become a dominant topic over the last few years.

This is due to ecological as well as economical reasons and thus nearly all branches of the building sector are included in energy saving efforts.

Due to their excellent insulating properties polyethylene foam profiles have become more interesting in recent years. Today they are a vital part in of window and facade systems.

PE foam profiles are able to lower the thermal transmission coefficient of a window or a facade significantly.

Energy costs can be saved and pollutant emissions can be lowered.

Sustainability: recycling & renewable resources

PE foam profiles are used for energy efficient building. But the sustainability issue does not end here.

As with other industrial products there is the matter of sustainable production and disposal.

Extruded PE foam profiles are mono-material products and can thus be recycled completely. Remains can be stripped of foreign materials such as adhesion tape or aluminium foil, shredded and again used for production.

In addition the polyethylene used for extrusion can be based on renewable sources such as sugar cane or sugar beet. These grow again every year, absorbing CO2 in the process and saving finite resources such as crude oil, which will require more and more effort to extract in the future.

The advantages of "BIO PE foam":

- Plant based resources grow again, absorbing CO2 in the process.

- Finite resources such as crude oil can be saved.

- BIO PE foam has the same properties as conventional PE foam.

- BIO PE foam - just like conventional PE foam - is completely recyclable.

- BIO PE foam is not or not significantly more expensive than conventional PE foam.

Sugar based PE foam does neither collide with preserving forest areas nor with food growing.

You are interested in a profile made of renewable PE foam? Please do not hesitate to contact us: Send your request