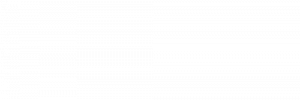

Sealing gaskets made of various materials

We employ different materials and manufacturing methods to develop customized products.

The following standard materials can be processed:

- cell rubber (various shore qualities)

- sponge rubber(various qualities)

- soft rubber (EPDM, CR, NBR, and many more)

- oam: e.g. polyethylene foam, melamine foam

- special materials such as Cellasto® or Viton®

You are unsure as to which material applies best to your sealing task?

Please contact us for advice: info@windowsafe.de

Cell rubber gaskets

Cellular rubber gaskets are light-weighed, ageing resistant and low cost. They can be used for sealing, insulating and damping.

They fit easily and perfectly into their surroundings. Reworking measures, set-up times and costs can be reduced significantly.

Cellular rubber is a porous, closed-cell material. The cells inside the rubber are not linked to each other. Because of that cellular rubber is airtight as well as watertight and doesn’t need an outer skin when used for sealing purposes as e.g. sponge rubber.

Cellular or cell rubber is manufactured with a foam agent to create air-filled structures. It is usually made of natural or synthetic rubber or a mixture of both. The most frequently used qualities are:

- EPDM (ethylene propylene diene rubber)

EPDM materials - for example cellular rubber - exhibit outstanding ozone, weather and aging resistance. Therefore they are especially suited for outdoor applications. - CR (chloroprene rubber)

Chloroprene rubber (polychloroprene rubber) is usually better known by its trade name Neoprene. Products made of CR cell rubber are highly resistant against acids, bases, oils and greases as well as weather conditions. They are also flame retardant. - NBR (acrylonitrile butadiene rubber)

NBR is a rubber quality that comprises acrylonitrile parts. The properties of its vulcanized products are highly depending on the polymer’s composition of nitrile. A low percentage of acrylonitrile causes high resistance to low temperatures. A higher ACN content will result in better resistance to oil and gasoline. All NBR qualities exhibit good aging behavior as well as a low abrasion rate. - SBR (styrene butadiene rubber)

SBR rubber is the world’s most commonly used rubber quality. It is cost-efficient and therefore used since the 1920s. SBR is often combined with other rubber qualities to improve its properties. A very common mixture is NR/SBR - NR (natural rubber)

Natural rubber is harvested mainly in the form of the latex from certain trees that originate from South America. The natives of the tropical Amazon Basin were calling the plants “ca-hu-chu“ which basically means „crying wood“. (Source: Wikipedia) Today rubber or caoutchouc trees are common in other parts of the world too, major cultivation areas being Thailand, Indonesia and Malaysia. Natural rubber exhibits good mechanical properties but very low to no resistance to chemicals, weather conditions or aging.

To all cellular rubber qualities applies: they all exhibit closed cell structures (even at cutting points) and are thus water, dust, air, light and gas tight up to 99,9% as well as highly insulating when it comes to heat and low temperature.

In addition their high elasticity provides excellent suspension and thus optimal damping effects when it comes to physical vibrations and impact sound.

All cell rubber materials can be splitted, die cut, water jet cut, glued and milled. Furthermore they can be coated or equipped with self-adhesives.

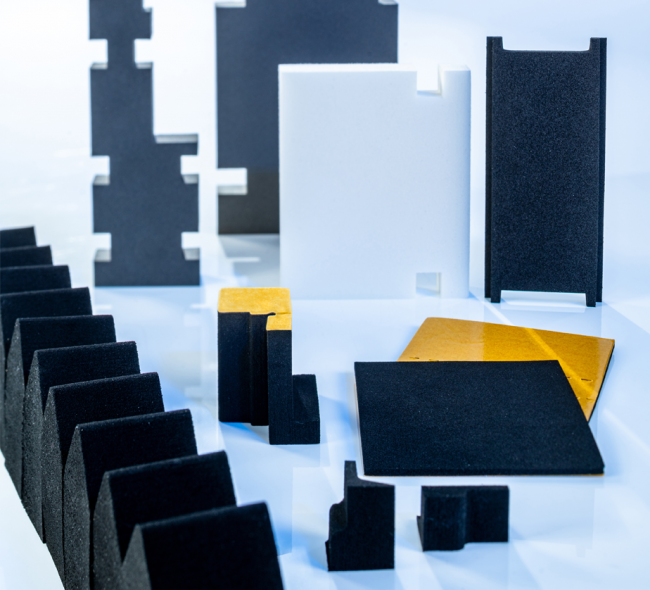

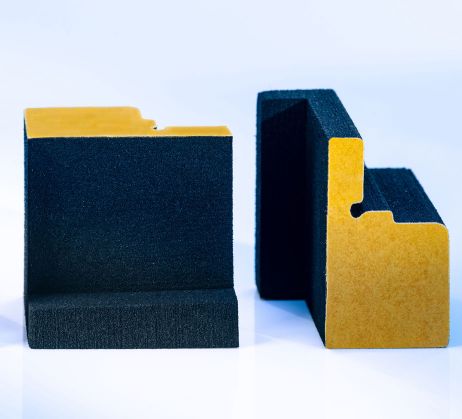

3D gaskets

The manufacturing of 3D sealing gaskets is one of our most distinctive competencies.

Producing 3D geometries can be realiszed by 3D waterjet but is still often highly complex and technically challenging because separate production steps are often necessary. Sometimes manual processing is required.

The application areas for 3D geometries are nonetheless variegated. For example:

- Adhesive tape does not only have to be applied to one but various sides of the gasket.

- Gaskets have to be assembled from different parts.

- Gaskets need to have undercuts, cavities or holes.

Send us a drawing of your special 3D sealing gasket: info@windowsafe.de

Serial production

Not all sealing gaskets feature a 3D geometry. Most gaskets are much less complex and thus suited for mass production via die-cutting.

Most materials can be die-cut including for example cell rubber, sponge and soft rubber as well as polyethylene foam. As long as the gasket's height is suitable even intricate shapes can be realized. Self-adhesive tapes can be included.

The manufacturing dies can usually be applied for years - thus reducing production costs, effort and time. So if the demand for a particular gasket will be foreseeable high in the future investing in a die-cutting tool can be economically profitable.

Send us a drawing of your flat gasket: info@windowsafe.de

Additional processing: lamination, perforation, coating

Self-adhesive gaskets are a standard that is often requested.

In addition to this we offer further kinds of processing:

- high temperature coating

- lining with other materials (PTFE, felt, etc.)

- perforation

- packaging

Find more information on our subpage "Sealing profiles, prototypes & special products" in the section on "coating".

Special gaskets made of special materials

In addition to standard materials such as cell rubber, EPDM or sponge rubber we also offer special materials for manufacturing sealing gaskets and other products.

Examples für special materials:

Cell rubber, partly closed-celled

Color: black

Density: ca. 90 kg/m³

Peak temperature: +140°C

Cell rubber, food safe

Color: grey

Density: ca. 115 kg/m³

Fire behavior: self-extinguishing

FDA certified

Cell rubber, super soft

Color: black

Density: ca. 75 kg/m³

Shore-Hardness 00: 25° (+/- 5)

EPDM, KTW approved

Color: black

Density: ca. 1.08 g/cm³

Certificates: KTW, W270

PUR foam, Cellasto®

Color: yellow

Density: 350 kg/m³

Quality: micro cellular polyurethane

[Cellasto® is a registered trademark of BASF AG]

PUR-foam, highly resilient

Color: green

Density: ca. 275 kg/m³

Range of use: up to 0,055 N/mm²

Load peak: up to 2 N/mm²

Silicone foam, highly temperature resistant

Color: grey

Density: ca. 250 kg/m³

Temperature range: -50°C up to +260°C

Melamine resin foam, ultra light-weighed & sound absorbing

Color: light grey

Density: ca. 10 kg/m³

Sound absorption rate: > 90% (50 mm, 2.000 Hz)